The selection of vortex blowers requires comprehensive consideration of multiple parameters and application scenarios. The following are systematic selection steps and precautions:

1. Clarify key parameters

Flow rate (air volume): The unit is usually m³/h or CFM. The required gas delivery volume is determined according to the process requirements.

Pressure:

Static pressure: The ability to overcome pipeline resistance (Pa or kPa).

Dynamic pressure: The kinetic energy of gas flow (if the system requires high-speed airflow).

Gas properties:

Media type (air, corrosive gas, flammable gas, etc.).

Temperature (high temperature requires special materials or cooling design).

Density (such as transporting high-density gases such as hydrogen, the motor power needs to be adjusted).

Power: Match the motor power (kW) according to the flow and pressure to avoid overload or inefficient operation.

2. Determine the application scenario

Vacuum adsorption: High vacuum pressure (such as -30kPa to -50kPa), select a high-pressure vortex blower.

Pneumatic conveying: Medium pressure (10~50kPa) with high flow, anti-clogging design is required.

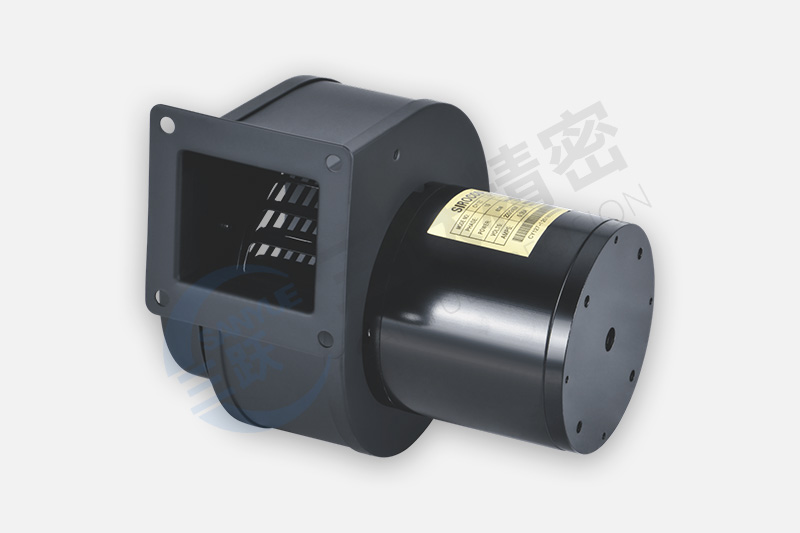

Ventilation and cooling: low pressure, large flow, ordinary centrifugal fan or low-pressure vortex fan can be selected

Special environment: explosion-proof (Ex certification), corrosion-resistant (stainless steel or coating), high temperature resistant (additional cooling system).

3. Selection steps

Calculate system resistance: calculate the total pressure loss through pipeline length, number of elbows, filter, etc. (fluid mechanics software or empirical formula can be used).

Reserve 10%~20% margin to cope with actual working condition fluctuations.

Match the fan curve

Check the performance curve provided by the manufacturer to ensure that the working point (flow vs. pressure) is in the fan high efficiency area (usually 60%~80% maximum efficiency range).

Select type

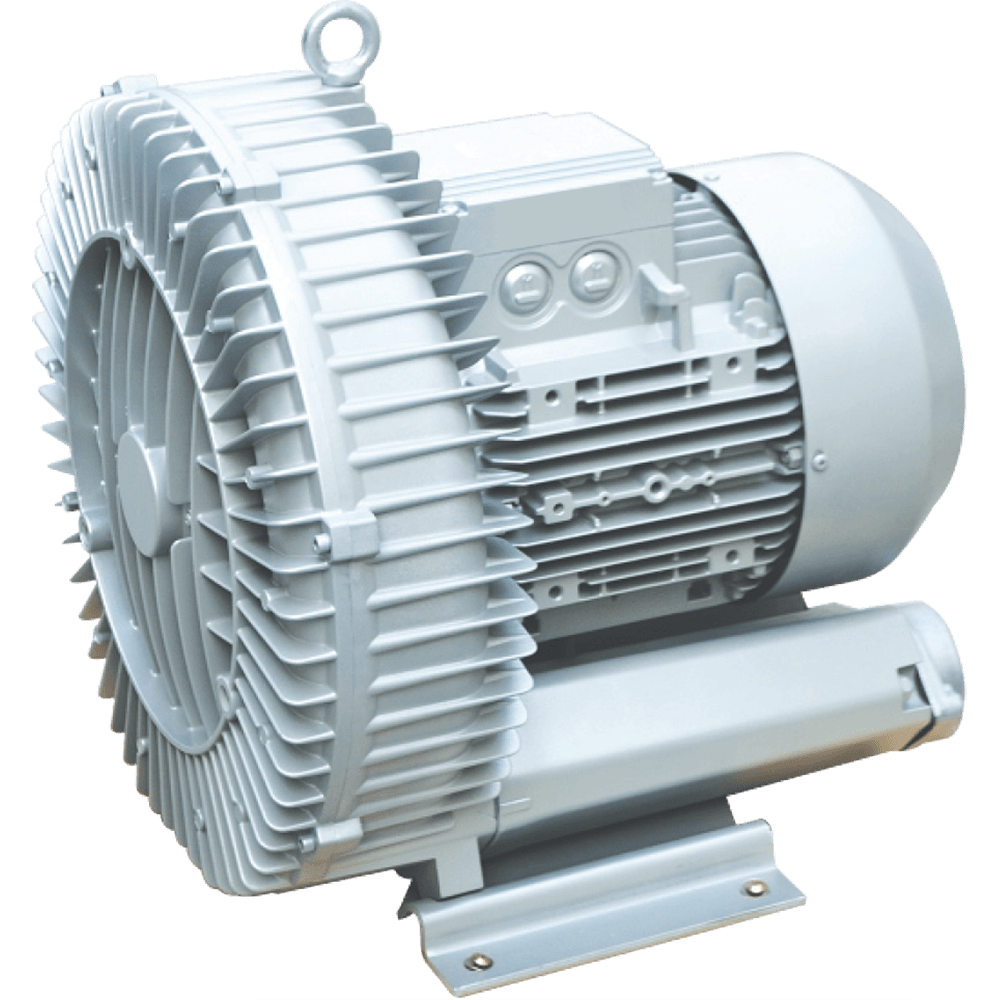

Single-stage vortex fan: pressure ≤50kPa, suitable for general use.

Two-stage vortex fan: pressure 50~100kPa, high vacuum or high pressure requirements.

Variable frequency model: energy-saving adjustment for scenes with large flow fluctuations.

Material and protection

Aluminum alloy: lightweight, economical, suitable for ordinary air.

Stainless steel: corrosion-resistant, used in chemical gas or humid environment.

IP protection level: IP54 or above is required for outdoor or dusty environment.

Accessory selection

Muffler: noise-sensitive areas (such as hospitals, laboratories).

Filter: clean gas requirements (such as food packaging).

Pressure relief valve: prevent overload damage to the fan.

4. Brand and cost trade-off

Imported brands: such as Germany's Busch and Japan's Hitachi, high precision, long life, high price.

Domestic brands: such as Jiangsu and Guangdong manufacturers, high cost performance, suitable for projects with limited budgets.

Maintenance cost: consider bearing life and lubrication method (maintenance-free or regular refueling).

5. Verification and debugging

Trial run: monitor whether the current, temperature rise, and vibration are normal.

Adjustment: fine-tune the flow/pressure to the best working condition through valves or inverters.

Common mistakes to avoid

Ignore gas temperature: high temperature gas will cause the fan to overheat, and the rated temperature range needs to be confirmed.

Unreasonable pipeline design: Too many elbows or too small pipe diameter will increase resistance and cause fan overload.

Oversize/undersize: Oversize will waste energy, and undersize cannot meet demand.

Through the above steps, the vortex fan model can be accurately matched. If the working conditions are complex, it is recommended to provide detailed parameters to consult the manufacturer for technical support. Dongguan Sanyue Precision Electromechanical Co., Ltd. is a technology-based enterprise focusing on the production of various specifications of high-temperature centrifugal fans, high-temperature motors, long-axis motors and other series of pneumatic products R&D, manufacturing, sales, and after-sales service. The products have passed CE\FCC\ROHS and other certifications. Contact number: 0769-88811878, 139 2845 2905 Mr. Chen.